GeoGro Landfill

With the development of cities, the amount of domestic waste generated has increased rapidly, and waste disposal has become a major problem in the process of urbanization in countries around the world.

New geosynthetics from GeoGro carry a five-year warranty that is effective from the date of shipping.

In case of dissatisfaction from our services or products, purchaser have the liberty to request a refund from us

Technical support is primarily provided by phone, whatsapp, e-mail or GeoGro customer support online.

GeoGro guarantees all new geosynthetics sold to be free of manufacturers’ defective workmanship and materials.

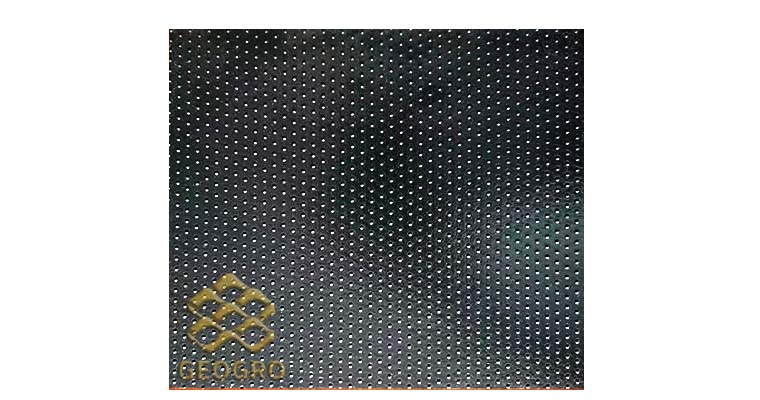

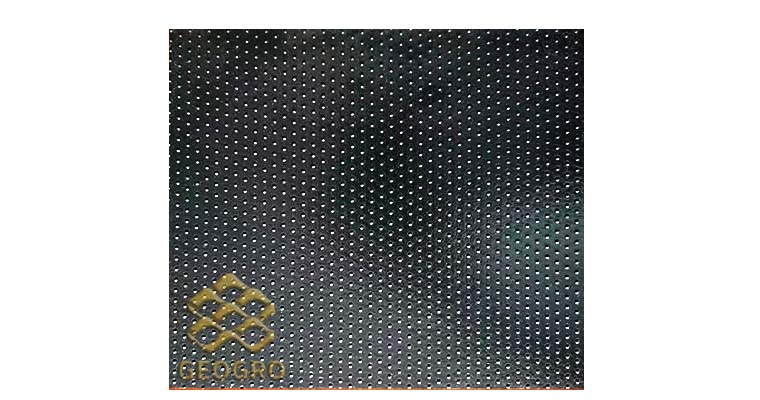

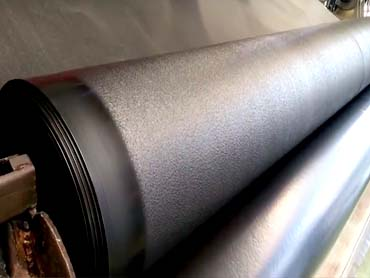

The textured geomembrane is composed of a concave-convex structure with a high friction coefficient. Compared with the smooth surface geomembrane, the rough surface geomembrane can not only be used for roof leakage prevention, landscaping, seepage prevention and water and soil conservation of farmland water channels, beach reclamation, landfilling in environmental engineering, three waste treatment and environmental remediation, prevention Desertification and other projects can also be used in engineering projects that require large friction coefficients such as steep slopes or side slope membrane surfaces that need to be covered with soil. It is the preferred material for engineering projects such as mountain construction and steep slope construction.

Material:HDPE/PVC/LLDPE

Roll Length:50-100m

Roll Width:1-16m

Color: Black,Yellow, Blue, White...

Thickness:0.5mm,1mm, 1.2mm, 1.5mm, 1.75mm 2mm, 2.5mm, 3mm

The textured geomembrane is composed of a concave-convex structure with a high friction coefficient. Compared with the smooth surface geomembrane, the rough surface geomembrane can not only be used for roof leakage prevention, landscaping, seepage prevention and water and soil conservation of farmland water channels, beach reclamation, landfilling in environmental engineering, three waste treatment and environmental remediation, prevention Desertification and other projects can also be used in engineering projects that require large friction coefficients such as steep slopes or side slope membrane surfaces that need to be covered with soil. It is the preferred material for engineering projects such as mountain construction and steep slope construction.

The textured geomembrane is divided into: single textured surface geomembrane, double textured surface geomembrane, and column point non-slip geomembrane.

GEOGRO's geomembrane has high impermeability coefficient, good heat resistance and cold resistance, and its use environment temperature is 110℃, low temperature -70℃. It can be used naked for a long time while maintaining the original performance. Our company's geomembrane is made of virgin polymer polyethylene plastic and carbon black particles without any preservatives, and it is safe and environmentally friendly in use without pollution.

GEOGRO as a professional and leading HDPE geomembrane and HDPE Pipe manufacturer with more than 27 years experience, has specialized in the production and marketing of geocell,HDPE geomembranes, LDPE&LLDPE geomembranes,HDPE pipe and fittings.

1)Good physical and mechanic performance.

2)High tearing resistance, strong deformation adaptability.

3)Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance.

4)Good adaptability to high and low temperature, non-toxicity, long service life.

5)Good waterproof, drainage, anti-seepage and damp proof effects.

6)Complete width and thickness specifications, low cost and easy installation.

| No. | Item | Parameters | ||||||||

| Thickness(mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

| 1 | Density(g/cm3) | ≥0.940 | ||||||||

| 2 | Yield strength(N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

| 3 | Breaking strength(N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

| 4 | Yield Elongation(%) | - | - | - | ≥11 | |||||

| 5 | Elongation at break(%) | ≥600 | ||||||||

| 6 | Tear Resistance(N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

| 7 | Puncture Resistance(N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| 8 | Carbon Black Content(%) | 2.0~3.0 | ||||||||

| 10 | Oxidation induction time at Standard(OIT)(min) | ≥60 | ||||||||

| 11 | Low temperature impact embrittlement performance | Pass | ||||||||

| 12 | Permeability coefficient of vapor(g-cm/(cm2-s.Pa)) | ≤1.0x 10-13 | ||||||||

| 13 | Size tolerance(%) | ±2.0 | ||||||||

With the development of cities, the amount of domestic waste generated has increased rapidly, and waste disposal has become a major problem in the process of urbanization in countries around the world.

At present, HDPE geomembrane anti-seepage structure design is adopted in China's domestic sewage treatment plants and petrochemical industries and some other fields. HDPE geomembrane has the advantages of high strength, good ductility, strong anti-seepage ability and good chemical stability.

In recent years, with the improvement of environmental protection regulations and the improvement of environmental protection requirements for construction projects, the environmental protection anti-seepage problems of mine tailings ponds have become increasingly prominent.

The HDPE geomembrane produced by our company can fully meet the integration of fermentation and gas storage in biogas digesters. The whole oxidation pond is fully enclosed by the anti-seepage material of HDPE geomembrane. The construction is simple, the construction cost is low, the sealing performance is good, and the use time is long. The HDPE geomembrane has strong anti-aging and anti-corrosion properties and good anti-seepage effect.