HDPE PIPE is a pipes made by high-density polyethylene material so that the resulting type of pipe that

can withstand higher compressive power. HDPE pipe is strong, pliable / flexible and resistant to chemicals

makes this product has a growing appeal. We are offering HDPE Pipe manufactured by word class technology,

automated extruder machine. Are also offering various size and diameter, thickness, quality as per client

requirement.

Sprinkler pipe

Sprinkler pipe also made from HDPE, in viewing of maximum output with limited time sprinkler system is commonly used In agriculture. We also deal in sprinkler irrigation system.

Toxic Free and Safe

Adopt sinopec quality environmental protection materials , toxic free and safe, Free of heavy metal additives, no scalling, no bacteria, green heatlth and environmental protection, in

lline with national health standard. Our products have passed the national ISO 9001 weight management system certification, safe and secure.

Stable Quality

Professional production equipment and technical process. The product produced has good flexibility, high impact strength, corrosion resistance

hdpe pipe has a smooth inner surface and non-adhesive properties, ensure that hdpe pipes have higher conveying capacity than conventional pipes, it also reduces the pressure loss of the

pipeline and the energy consumption of the water.

Secure Connection

HDPE pipe is connected by a unique electric hot melt method, the strength of the joint is higher than the strength of the pipe body. Flange connection between hdpe pipe and other pipes.

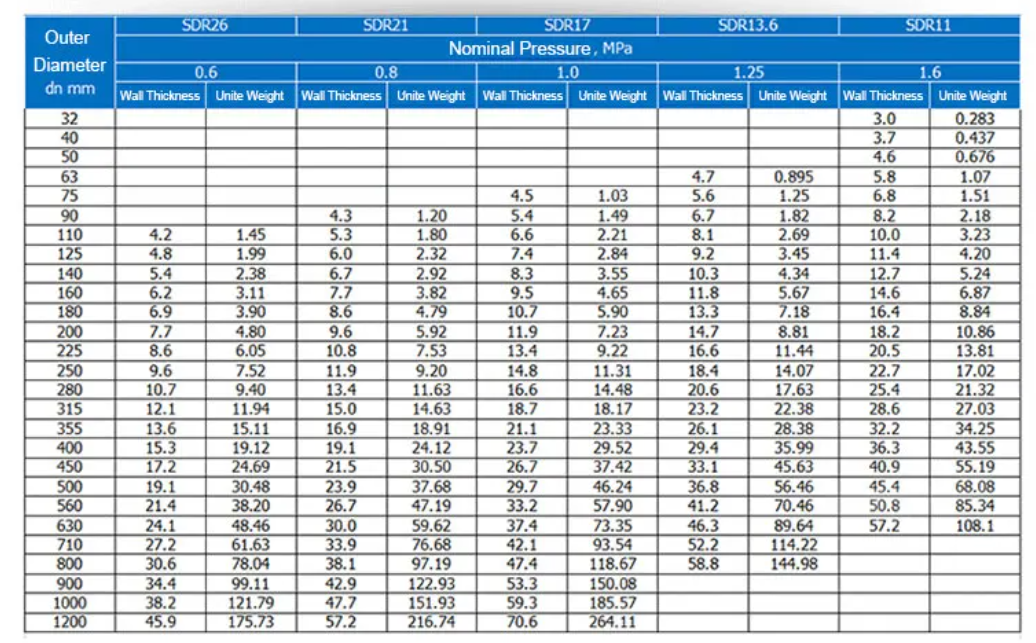

HDPE pipe sizes are from DN32 to DN1200. The pressure grade is between 0.6mpa and 1.6mpa, with 5 grades. HDPE pipe in the temperature of 190 ℃ n240 ℃ between will be melt, using this feature, the pipe (or pipes) a good contact with both parts of the melt, And maintain the appropriate pressure, after cooling the two can be firmly integrated. Therefore, the connection mode of PE pipe is different from that of u-pvc pipe. Generally, the two methods are electric hot melt connection and hot melt butt joint. When DN is greater than or equal to 75, hot-melt butt joint or electric melt socket connection is adopted. Connect with different materials using flange or thread connection.