GeoGro River wetland, Fish ponds and Biogas digesters

The HDPE geomembrane produced by our company can fully meet the integration of fermentation and

gas storage in biogas digesters. The whole oxidation pond is fully

enclosed by the anti-seepage material of HDPE geomembrane. The construction is simple, the

construction cost is low, the sealing performance is good, and the use

time is long. The HDPE geomembrane has strong anti-aging and anti-corrosion properties and good

anti-seepage effect.

1)In order to ensure the anti-seepage effect and service life of the structure, it is recommended to use

HDPE geomembrane with thickness more than 0.75 mm.

2)In order to reduce the weld and construction period, the width of 7 meters or more

should be selected. The area of the pond should considering the edge part (1 meter

circumference along the side wall), and a residual of 7% is expected. (Anchoring, lap

joint and leak repair welding).

3)After the construction of the biogas slurry pool is completed, water of about 0.8 meters depth

shall be injected as early as possible to protect the geomembrane from being exposed to the sun and

prolong the service life of the geomembrane.

Key points of anti-seepage GeoGro's geomembrane slope protection

technology:

Key points of anti-seepage GeoGro's geomembrane slope protection

technology:

1) The base surface of the slope protection is smooth.

Regardless of whether it is rebuilding an old pond or building a new pond, the base surface of the slope

protection must be leveled before laying. The soil of the slope ridge must be dry, the slope surface must

be free of unevenness, and there must be no protruding stones or sharp objects on the surface. The slope

surface must be flat. Take the method of cutting and backfilling the soil layer and then ramming it to

make it solid. If there are many gravels on the slope of the ridge, a thin soil layer can be used to cover

it and then the method of compacting it can be used to avoid direct contact of gravel or sharp objects

with the membrane to extend the length. The service life of the membrane. The embankment of the newly

built pond is tamped and then laid. In some cases, after a period of use, uneven settlement will occur,

and the slope will appear uneven. You can level it again when the ridge is hardened and the pond is dried.

Use a level gauge to stake out the cable on the slope surface 0.3m higher than the water storage depth, so

that it is laid out smoothly and compliantly, without wrinkles.

2) The groove at the bottom of the slope foot in the pool.

For flat-bottomed ponds, at the bottom of the

slope toe, dig a trench with a depth and width of about 30cm each on the bottom of the bottom of the slope

as the standard; for pot-bottom-shaped ponds, excavate a surrounding trench at the hard bottom below the

wall groove.

3) Leveling at the horizontal line

At the horizontal position, a width of 30 cm is flattened along the cross section, or an anchor trench

with a depth of 10 cm and a width of 20 cm can be opened in the cross section to fix the impermeable

geomembrane under pressure.

4) Pond ridge seepage water treatment.

Mountainous areas are mostly trapezoidal ponds, and most adjacent ponds have height differences. Some pond

ridges have poor soil quality and strong water seepage. In the rainy season, rainwater tends to seep into

the pond ridges, which will cause the geomembrane to expand and swell outward. If there is a height

difference between adjacent pond ridges, burying geomembrane on the slope of the upper pond ridge can

prevent the lower one from bulging; for pond ridges with strong water seepage and rain, the surrounding

trenches should not be dug too deep, with a length of 30cm That is, when burying, the bottom of the trench

is laid flat and spaced a certain distance with wooden sticks or bricks

After the rock is compacted with the membrane, the soil is compacted and the seepage will naturally

overflow; it is also simple and practical to insert a water-conducting plastic pipe on the slope

protection surface. Method to prevent swelling and swelling.

5) Laying the inlet and outlet of the pond.

The membrane at the inlet and outlet can be cut and reserved according to the size of the pipe. The

position of the outlet can be fixed by casting cement mortar, or can be surrounded by woven bags of sand

and soil.

6) The laying of geomembrane.

In order to facilitate the construction, the geomembrane should be cut and spliced according to the width

of the geomembrane and the length of the site. The cut and spliced film can be rolled on steel pipes or

bamboo sticks and transported to the slope for laying. The geomembrane laying is divided into grooves and

slopes. Lay three parts horizontally and horizontally on the top of the slope. Roll paving in the

direction of the slope first and then adjust it. The paving of the slope is done from bottom to top. The

geomembrane and the slope are flat, leaving no gaps, no protrusions and wrinkles. The top and toe of the

slope are fixed by anchoring ditch or other reliable methods. To prevent it from sliding. Strive for

smoothness, moderate tightness, and not overtighten. When backfilling the trench, do not damage the

geomembrane, and do not use heavy machinery or vibration compaction. Laying should be carried out in no

wind or rain. Construction personnel should wear flat-bottomed cloth shoes or soft rubber shoes. Spike

shoes are strictly prohibited to avoid stepping on the geomembrane.

GeoGro's geomembrane biogas digesters are divided into

two types: bag type and cover type.

GeoGro's geomembrane biogas digesters are divided into

two types: bag type and cover type.

In the GeoGro's geomembrane bag type biogas digester, the plastic film is first processed and

heat-welded into

an air bag, and a round soil pit with a diameter of 8 meters equal to the air bag is dug on site. An

annular cement water seal is placed on the upper pocket of the soil pit (with photos). The water seal

ring is prefabricated with cement, and its outer edge diameter is 2.7 meters, the inner edge diameter is

2.3 meters, and the water tank is 150 mm wide and 250 mm deep. Then cut the air bag into two sections.

The lower half should be able to roll over and cover the water tank; the upper half is the cover of the

digester with a gas pipe. After the fermentation liquid is added, cover the lid. The openings of the

upper and lower parts of the air bag should be attached together, and flattened with clay (200 mm

thick), and finally sealed with water in the groove. The plastic-film biogas digester made of thousand

carbon black is a low-pressure tank, and generally this sealing method will not leak gas.

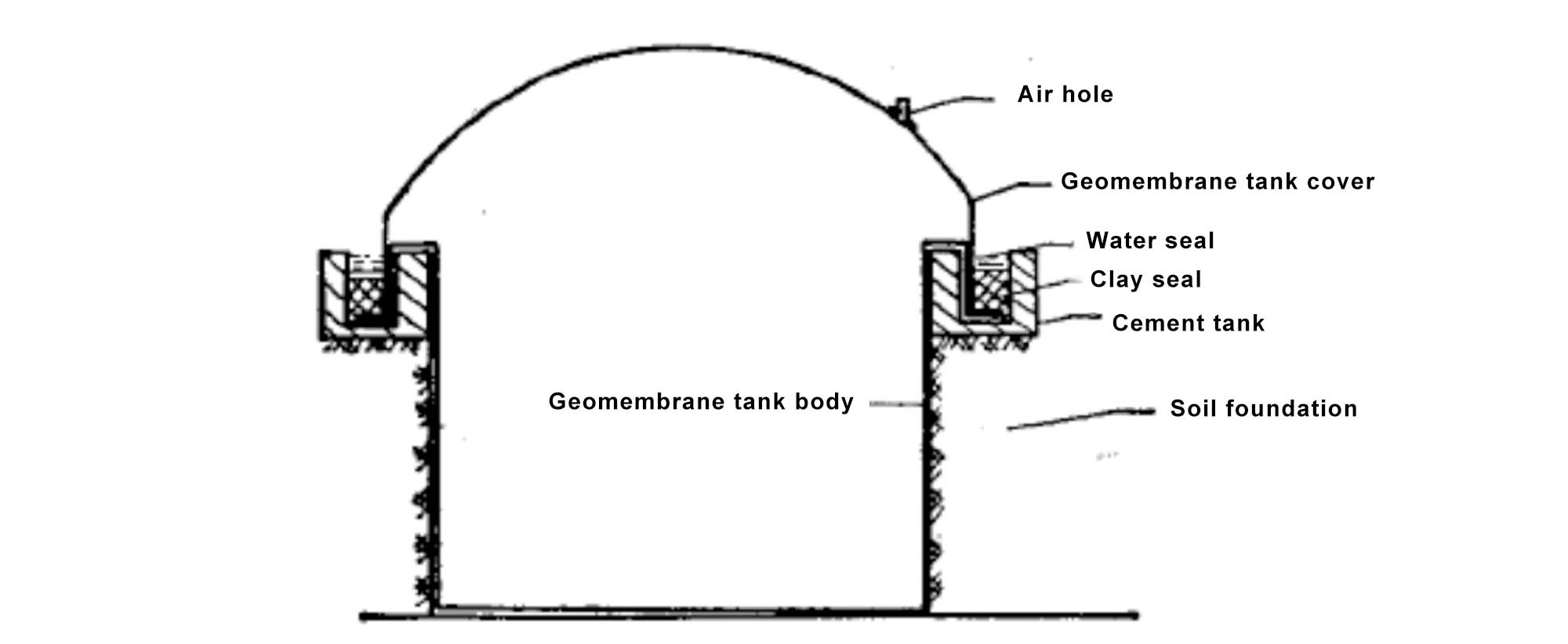

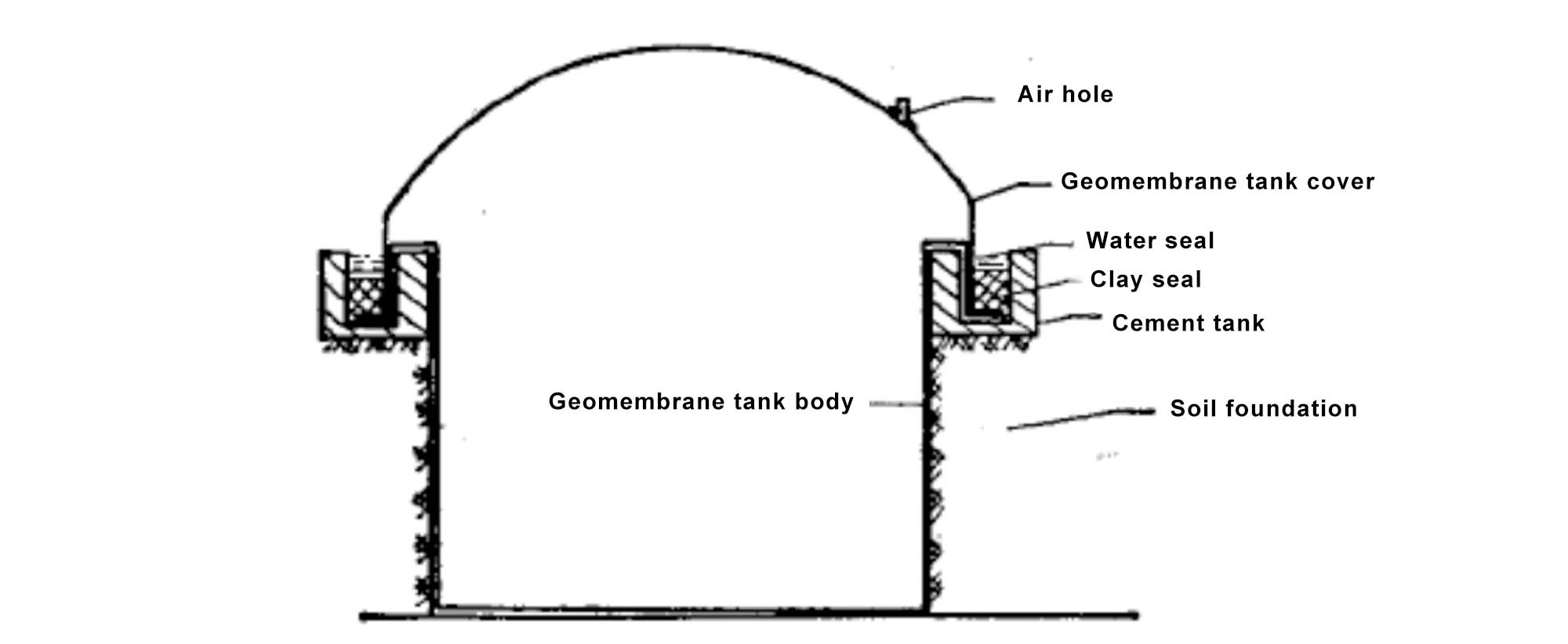

The difference between the geomembrane cover type biogas digester and the bag type digester is that the

lower half of the biogas digester is an open tank with a cement and brick structure, and the upper half

is covered by a plastic membrane. The installation and sealing are the same as those of the bag-type

pool.

GeoGro's geomembrane has the characteristics of high strength, low temperature resistance, aging

resistance, and

easy adhesion. Using it as a construction material for biogas digesters is easy to maintain and easy to

operate. It overcomes the shortcomings of general hydraulic biogas digesters that are difficult to

discharge, and it can feed and discharge 2-3 times a year, saving labor and time.

Key points of anti-seepage GeoGro's geomembrane slope protection

technology:

Key points of anti-seepage GeoGro's geomembrane slope protection

technology:

GeoGro's geomembrane biogas digesters are divided into

two types: bag type and cover type.

GeoGro's geomembrane biogas digesters are divided into

two types: bag type and cover type.