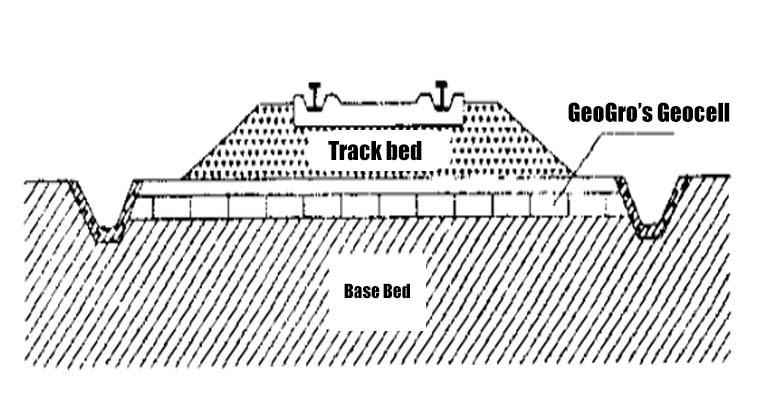

Placing the geocell at the bottom of the track bed (top of the foundation bed) can improve the bearing characteristics of the roadbed, so that the stress of the load transferred to the soil under the cell is reduced, so the deformation of the soil is also reduced. In the case of a cell, under normal circumstances, the excavation depth of the soft soil of the base bed only needs to be equivalent to the height of the cell, and there is no need to deepen the side trench, which can reduce the amount of soft soil excavation and greatly reduce the difficulty of construction. Shorten the construction period and save investment.

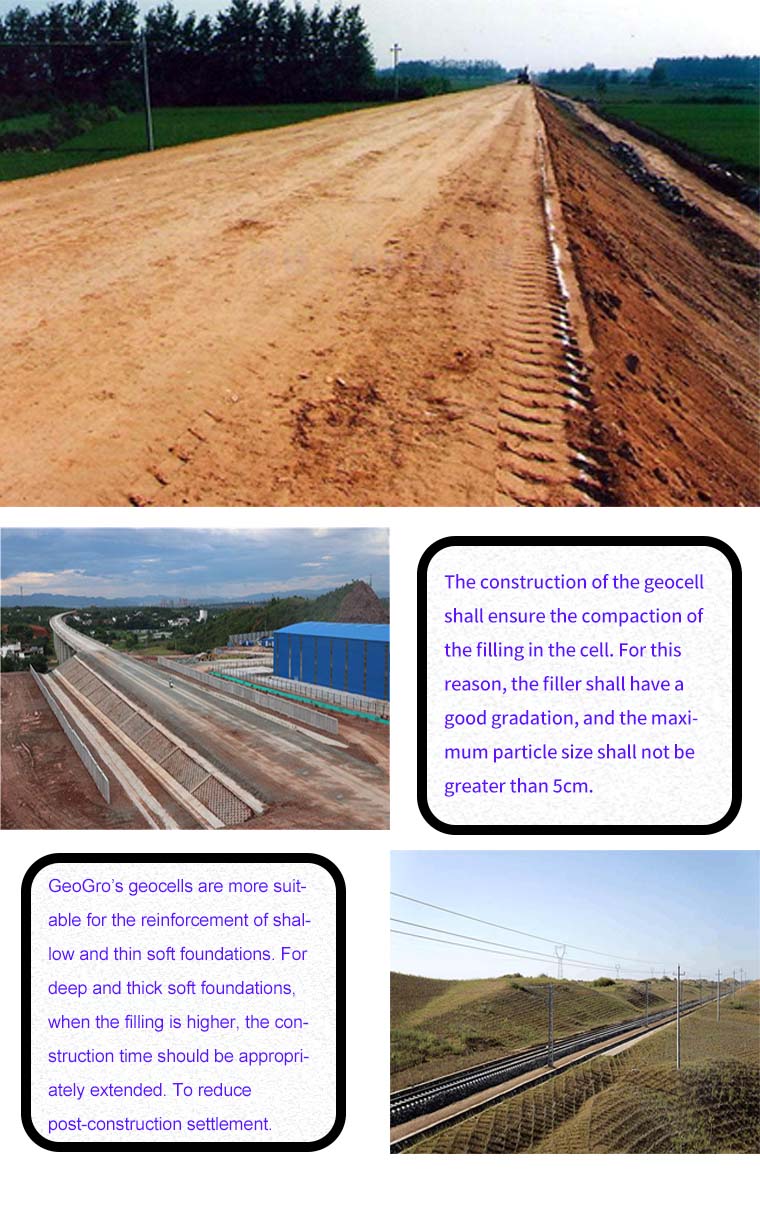

First of all, the quality of the permeable soil of the cushion should be ensured, and the content of

clay and organic matter should not exceed limit. Permeable soil is a favorable condition for drainage of

soft foundations. Then there is the flatness of the cushion surface, there should be no potholes that

cause the geocell to hang in the air

and there should be a lateral slope on the surface. Since the stiffness of the reinforcement layer of

the geocell will directly affect the reinforcement effect, the construction of the geocell should not

only be stretched to the required size, but also should ensure that the filler in the geocell has the

best density. To this end, it is necessary to ensure that the filler gradation is good, and the maximum

particle size shall not be greater than 5 cm.

For the safety of construction. In areas where the soft

soil layer is thicker, the mechanical strength is poor, and the fill is higher. Observation piles are

set every 20 m at 2.0 m outside the toe of the

embankment on both sides of the subgrade. Observe at any time during the filling process, and it is

required that the vertical displacement does not exceed 15 mm per day, and the lateral displacement does

not exceed 20 mm per day. Otherwise, the filling should be slowed down or suspended. The results of the

construction observation of this test project show that

The filling rate is not controlled.