The pond liner produced by GeoGro can be used for long-term maintenance-free use after the laying is

completed; it will not produce harmful substances that harm plants and fish in the pond; it can adapt to

structural deformation such as uneven settlement without cracking; it is convenient and quick to

construct.

The materials commonly used for pond lining are hdpe, epdm, pvc.

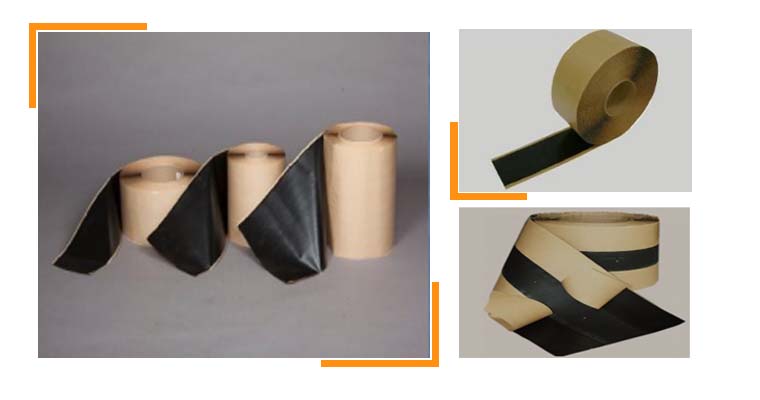

The EPDM pond Liner produced by GeoGro uses EPDM rubber with excellent ozone aging resistance as the main

raw material, supplemented by butyl rubber, natural rubber, carbon black, and vulcanizing agents.

These raw materials are high-grade waterproof membranes made by mixing, calendering, vulcanizing and

other processes. It not only has high tensile strength, but also has excellent elongation, resilience

and low temperature resistance. Its particularly excellent resistance to ozone aging is unmatched by

other waterproof membranes. According to the demonstration by the American waterproofing community who

first developed this kind of product, its longest life span can reach more than 50 years.

GEOGRO's pond liner has high impermeability coefficient, good heat resistance and cold resistance, and its use environment temperature is 110℃, low temperature -70℃. It can be used naked for a long time while maintaining the original performance. Our company's geomembrane is made of virgin polymer polyethylene plastic and carbon black particles without any preservatives, and it is safe and environmentally friendly in use without pollution.

GEOGRO as a professional and leading pond liner and geocell manufacturer with more than 27 years experience, has specialized in the production and marketing of geocell,HDPE geomembranes, LDPE&LLDPE geomembranes,HDPE pipe and fittings.

The pond liner produced by GeoGro has the

following technical characteristics:

1) High temperature resistance, which can maintain stable

physical and chemical properties under high alkalinity and high corrosion conditions.

2) It has a good coefficient of friction with the base layer,

which can ensure that the anti-seepage layer and the base layer (or side wall) do not have a large

degree of displacement and sliding.

3) Longitudinal and transverse tensile strength and

elongation are large, which can delay or prevent the trend of reflection crack growth caused by uneven

settlement and deformation.

4) Strong puncture resistance. Under the design height, it

can withstand the puncture of local gravel at the base level without being damaged.

5) Good anti-seepage performance, and can maintain excellent

anti-seepage performance under the conditions of use without leakage.

6) The seaming method is reliable.

7) Excellent resistance to high temperature lye corrosion and

aging resistance, and maintain normal operation within the service life of the pond design.

|

No.

|

Item

|

Parameters

|

||||||||

|

Thickness(mm)

|

0.30

|

0.50

|

0.75

|

1.00

|

1.25

|

1.50

|

2.00

|

2.50

|

3.00

|

|

|

1

|

Density(g/cm3)

|

≥0.940

|

||||||||

|

2

|

Yield strength(N/mm)

|

≥4

|

≥7

|

≥10

|

≥13

|

≥16

|

≥20

|

≥26

|

≥33

|

≥40

|

|

3

|

Breaking strength(N/mm)

|

≥6

|

≥10

|

≥15

|

≥20

|

≥25

|

≥30

|

≥40

|

≥50

|

≥60

|

|

4

|

Yield Elongation(%)

|

-

|

-

|

-

|

≥11

|

|||||

|

5

|

Elongation at break(%)

|

≥600

|

||||||||

|

6

|

Tear Resistance(N)

|

≥34

|

≥56

|

≥84

|

≥115

|

≥140

|

≥170

|

≥225

|

≥280

|

≥340

|

|

7

|

Puncture Resistance(N)

|

≥72

|

≥120

|

≥180

|

≥240

|

≥300

|

≥360

|

≥480

|

≥600

|

≥720

|

|

8

|

Carbon Black Content(%)

|

2.0~3.0

|

||||||||

|

10

|

Oxidation induction time at Standard(OIT)(min)

|

≥60

|

||||||||

|

11

|

Low temperature impact embrittlement performance

|

Pass

|

||||||||

|

12

|

Permeability coefficient of vapor(g-cm/(cm2-s.Pa))

|

≤1.0x 10-13

|

||||||||

|

13

|

Size tolerance(%)

|

±2.0

|

||||||||

GeoGro owns 23 production lines for HDPE pipe &fittings, 5 HDPE Geomembrane production lines now, also has established a national-standard laboratory for in-house quality control and built a strict quality control system in all aspects from raw materials testing and production processes to final product quality testing.Not only is stringent internal quality control carried out at GeoGro, but regular testing and analyzing of our product performance is implemented by authoritative testing organizations in Europe and theUnited States. The management system is certified by ISO9001 and GeoGro’s products have passed the CE certification authorized by BTTG.

GEOGRO welding machine can weld geomembrane of various thickness and are applicable for welding of all thermal-fused material such as HDPE, LDPE, EVA, PVC, ECB, PP and so on. The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It can maintain a constant speed on the condition of creeping, vertical creeping and variable road load. Also this series of welding machine is stable in performance despite of external temperature and voltage variation.

GEOGRO's welding machine specification

|

Brand & Type

|

GEOGRO's Geomembrane Welding Machine GW800D

|

|

Voltage

|

220V/Customized

|

|

Power

|

800W

|

|

Frequency

|

50/60Hz

|

|

Welding Speed

|

0.5-5m/min(Adjustable)

|

|

Heating temperature

|

0-450℃(Adjustable)

|

|

Thickness of material

|

0.2mm--1.5mm(Monolayer thickness)

|

|

Overlap width

|

100mm

|

|

Welding width

|

12.5mm×2, interior

cavity 12mm

|

|

Seam strength

|

≥85% base material(tensile resistant in shear direction)

|

|

Net Weight

|

5kg

|

|

Gross Weight

|

8.5kg

|

|

Plug Standard

|

Euro Plug/ U.S.

Plug/British Plug/Plug adaptor

|